The anilox is considered to be the heart of the printing press. During the production process the tolerances are within micrometers. This counts for the body, the bearings, the journals and just as much for the ceramic layer on top and its laser engraving technology creating the volume. Once the roll or sleeve is delivered to you, we expect you to treat it with the utmost care as well in order to create the longest possible lifetime.

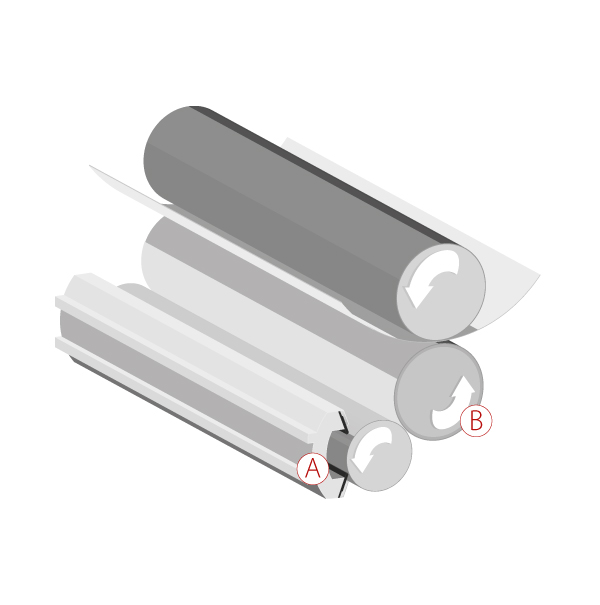

The anilox roll/sleeve is considered to be the heart of the flexographic printing press. It transfers a determined amount of ink from A (ink reservoir / rubber metering roll) to B (printing plate).

This requires a high level of precision. If the surface of the anilox roll/sleeve is damaged, an unequal layer of ink will be transferred onto a printing plate, creating poor quality print jobs. Therefore, it

is of the utmost importance that an anilox roll/sleeve is treated in the best possible way. When used/cared properly the lifetime of an anilox roll/sleeve is 2 years or even longer. 6 simple steps can help you achieve this:

- Decent handling upon arrival

- Correct installation into the press

- Right Use & Care during the daily print & production process

- Daily cleaning of the anilox rolls/sleeves

- Regular Deep-Cleaning of anilox rolls/sleeves

- Performance of regular audits of your anilox rolls/sleeves

We developed a Use & Care Guide with detailed advice on the above mentioned topics. You want one for free? Download the guide here below!